How Keyport Started - Part I

Way back in 2004, I was fresh out of college. I had been working at an architectural firm in Santa Monica for the previous year or so and I loved my job. I worked in the field, riding my motorcycle from various architectural job sites around downtown Los Angeles. I rode my motorcycle nearly everywhere because I could not stand driving a car and sitting in L.A. traffic.

Splitting lanes on my bike was fast and exhilarating. I always said riding my bike in L.A. traffic was like playing a video game with one life, always on high alert, watching every car like it could suddenly cut me off. The most challenging part about riding to my job sites was carrying all my gear. I had never heard the term Everyday Carry, since it wasn’t invented yet, but I was certainly very conscience of every piece of gear I was carrying daily. Most days I needed to carry my computer, drawings, specs and various submittals (samples) for 2-3 different jobs along with my hard hat, and of course my motorcycle helmet and gloves. This was quite a challenge but what actually annoyed me the most about my frequent commutes was my keys.

Part of my morning routine was to lay everything out and only take what I needed for that day. To prevent my keys from scratching my motorcycle and making noise while moving at high speeds, I would keep my other keys separated from the bike key while I was riding. The bulky keychain stabbing my leg in my pocket was frequently on my mind. The simple truth of this story is, I hated my keys. So I set off into a paradoxical journey to invent a way to tame them.

I started brainstorming to come up with a way to hold all my keys in one minimal device, where I could deploy the key I needed, and the other keys would not dangle freely from a loose keychain. I started sketching my ideas and building numerous prototypes from my sketches with some basic tools and a Dremel. As the designs progressed, they went from a simple pin through the heads of the keys similar to many key organizer devices you see today, like KeySmart, KeyBar, and our own Keyport Pivot. This didn’t work well with my motorcycle key because it had a large plastic head. So, I chopped off the plastic head with a hammer and chisel and then I even removed most of the metal head of each key with a Dremel. Then I drilled new holes where necessary, and made a small case for them out of sheet metal. I was extremely happy with the results and used my prototype every day for nearly a year. It actually made using my keys enjoyable.

First working prototype was built in 2004, using some basic tools and sheet metal.

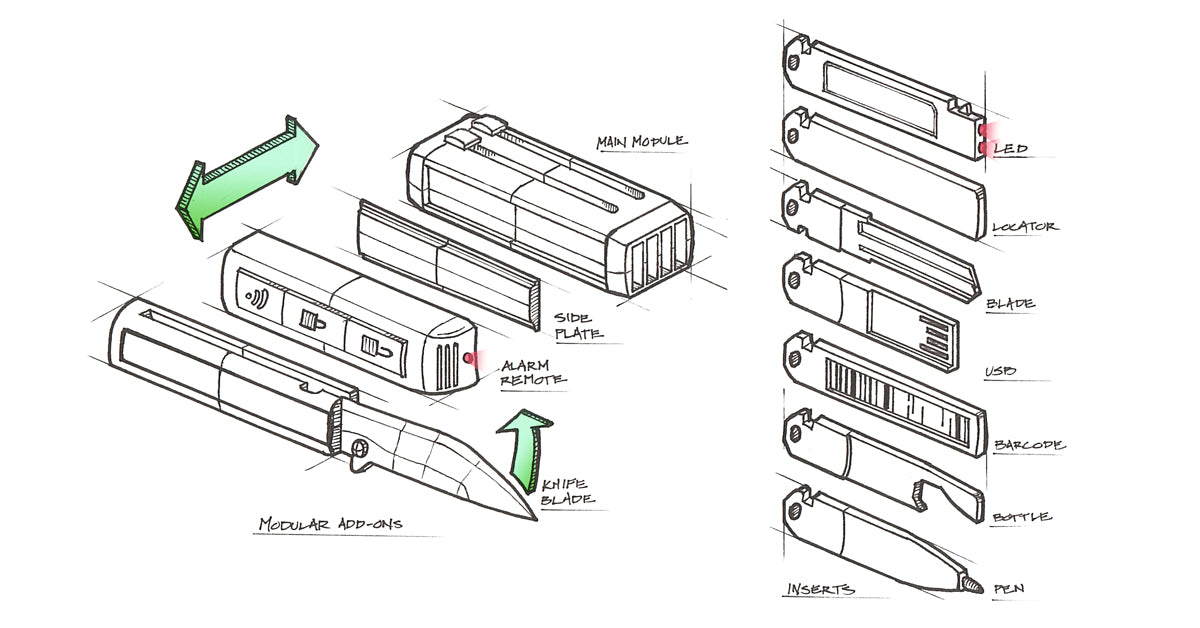

I kept my idea a secret for the most part, but when I started showing some of my friends and coworkers what I called the “Joshua Key", everybody wanted one. Then, an even better idea came to me, a sliding mechanism to deploy each key with my thumb, and the idea for the first Keyport Slide was born. I started thinking of all the tools and tech features that could be integrated into the devices I was building along with my keys. With all these different ideas going through my mind and growing interest, I started to consider what it would take to commercialize the product. I had zero experience in entrepreneurship, business, or product design. I was perfectly happy with how my career in architecture was going and I loved my job. Now, keep in mind, this was before crowdfunding and 3d printing, and it was not easy to prototype a concept like it is today, back in 2004.

I started doing research on how to start a business, get a patent, raise startup capital, etc., and after considerable thought, I decided to pause my architectural career, move to Las Vegas, and make my concept a reality in 2005. I raised some cash from friends and family to get going, hired an industrial design firm, got a lawyer, and I was off and running with big aspirations. I came up with over 10 concepts and took the Slide and Pivot concept to the next level with some SLA and machined prototypes.

This prototype and many others was created back in 2005.

The Slide concept was definitely more popular with everyone I showed it to, compared to the Pivot concept, so I focused all of my efforts on the Slide, determined to bring it market as soon as possible. I was beginning to realize the complexity and massive scale of the key market, not just in the U.S.A., but worldwide. While the sliding mechanism seemed like a simple concept, it proved to be the beginning of a very difficult journey. Here’s why... there are tens of thousands of keys in the world with different profiles, thicknesses, materials, etc. In order to make the sliding mechanism work effectively, the keys heads would need to have the same width, height, and thickness. I either had to re-create all the key profiles from scratch, or build a machine that could convert existing keys into Keyport Slide compatible keys we would eventually call Blades. The goal was to create a solution that worked with 99% of the world’s keys, and that goal proved to be incredibly challenging.

In April of 2007, I had made decent progress but I was running on fumes, and had to figure out a way to raise more money. I decided to do a public launch of the concept and start an interest list to prove there was a market for my idea to investors. I built a website…and started to prepare a press release. Before the press release was done, I sent a link to my new website out to 2 or 3 blogs and something extraordinary happened.

Original Keyport website key-port.com, launched in April 2007.

When I woke up the next morning, there were already over 3000 emails on my interest list! Notcot did a post that day and the post made the rounds very quickly, getting Top 10 honors on digg.com, which was a big deal at the time. For the next week Keyport was published on nearly 50 blogs worldwide, including Gizmodo, Uncrate, Wired, Core77, Yanko Design and many more. By months end, I had over 10k sign ups on the interest list.

Josh still has his 2003 Suzuki GSX-R 1000 that was the catalyst for the Keyport idea.

The Paradox of Entrepreneurship

It’s now about 15 years since I first had the idea for Keyport. I literally knew nothing about keys other than I hated them. I had to learn everything about them to reinvent the way they are carried. To make Keyport work, I’ve had to reverse engineer the industry to design a system to convert all types of keys including transponder chipped auto keys, plastic headed keys, high-security keys, and many more, to Keyport Blades. To be continued...

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.