Slide 4.0 LE1 Prototype Demo

We received a few initial prototypes of the Slide 4.0 LE1 a couple weeks ago and have been putting them to the test with daily use. Typically, with a prototype, there will some issues with the parts that need to be adjusted on the spot since the parts are made in small quantities using processes that aren't used in mass production. For example, there are two MIM (Metal Injection Mold) parts in the design which require expensive tooling for mass production. To prototype these parts, we had them made with metal 3D printing. The parts are very accurate but they don't have the smooth perfect surface texture like the MIM parts will have. They came very dull with a porous texture with sharp edges that had to be improved manually with sandpaper and a rotary tool.

3d-printed stainless steel parts before and after polishing and de-burring. 3d printed metal is very porous compared to what the production MIM parts will look like but they are accurate enough for prototyping.

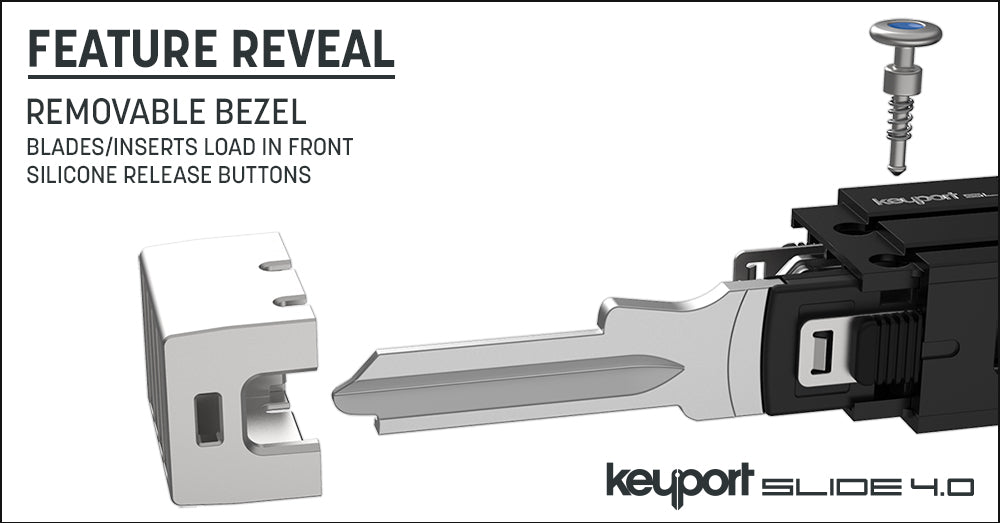

We also identified a few other issues that will have to be improved in order to make some of the features function optimally. Some of these issues with the prototypes could be fixed by filing, grinding, etc. For example, the removable link in the back has a spring that was too thick and rigid, so I just cut some relief slots in it with a tiny cutting wheel. This is obviously a temporary fix. I also updated the design and sent the files off to get new parts made. In addition, the retainer that holds the Bezel in place and includes the Module release tab needed a few minor updates. I also updated those parts and sent them off to get the new version made. So, we have to wait on those parts to test the fully assembly again. They are due to arrive next week.

Here's a list updates we're making to the current design:

- Module Release Tab - Testing different shapes to make it more comfortable. The current jimping is a little rough on the thumb.

- Scales - We're looking at making the scales out of stainless steel instead of aluminum for better edge retention

- Link - Fine tuning the spring tension

- Screws - Planning to make the screws black in the LE1

Keyport Slide 4.0 LE1 Prototype Demo

We were originally hoping to start pre-orders in October, but we need to feel comfortable with our production timeline before we launch. We know how excited everyone is to get the new Slide, and we're doing everything we can to move this final design phase along as quickly as we can. Thank you for your continued patience.

Remember, when it's time to launch pre-orders, we will announce it in this order.

- Keyport Discord - VIK Channel

- Keyport Discord - Slide Channel (Join Here)

- Keyport SMS (Join Here)

- Keyport VIP Email List (Join Here)

- Keyport Socials - Instagram, Twitter

Be sure to join our Discord if you want to be sure to get one in the first tier.

Catch up on previous updates here:

Update 1 - Keyport Slide - What's Next?

Update 2 - Keyport Slide 4.0 Is Coming

Update 3 - Keyport Slide 4.0 LE1 Introduction

Update 4 - Slide 4.0 LE1 Module Release Lever

Leave a comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.